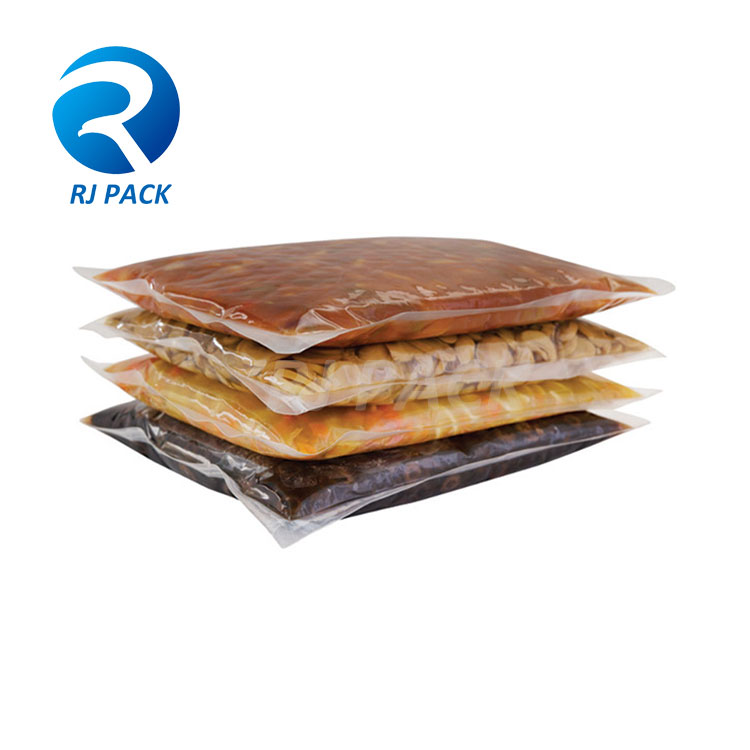

126℃ Retort Pouches

126℃ Retort Pouches can be used in a wide range of food and drink with its superior shelf life of more than 1 year at room temperature of retort pouch-packaged foods with very high barrier properties of OTR and WVTR. As a major factory on manufacturing Retort Pouches, we have obtained ISO and BRC certificates, supply suitable price and best quality, good in European and American markets.

Send Inquiry

126℃ Retort Pouches

126℃ Retort pouches is a sterilizable flexible pouch constructed of a thin, bonded film that can withstand processing a product inside at up to 135℃(275℉) for 30 – 50 minutes. It is probably most familiar to the public for tuna fish in a pouch, one of the industry’s earlier adopters.

RJ pack takes great pride in being one of the top flat bottom packaging suppliers in the world, with rich experience, we're professional to provide packaging solution for you.

1.Product Introduction

126℃ Retort Pouches has been considered the most significant advance in food packaging since the metal can and has the potential to become a feasible alternative to metal cans and glass jars.

Some different plastics layers used in Retort Pouches which include;

polyester (PET) – provides a gloss and rigid layer, may be printed inside

nylon (bi-oriented polyamide) – provides puncture resistance

aluminium (Al) – provides a very thin but effective gas barrier

food-grade cast polypropylene (CPP) – used as the sealing layer

2.Product Parameter (Specification)

|

Item |

126℃ retort pouches |

|

Size&thickness |

Customized, from 0.5oz to 30kgs |

|

colors |

Up to 10 colors |

|

Material |

PET, NY, CPP, Al2O3 PET, Foil etc. All In food grade and compliant with EU and FDA standard. |

|

Quality Control |

Advanced Equipment and Experienced QC Team will check material, semi-finished and finished products strictly in every step before shipping |

3. 126℃ Retort Pouches Feature And Application

1). Pressure-temperature:130℃for half hour

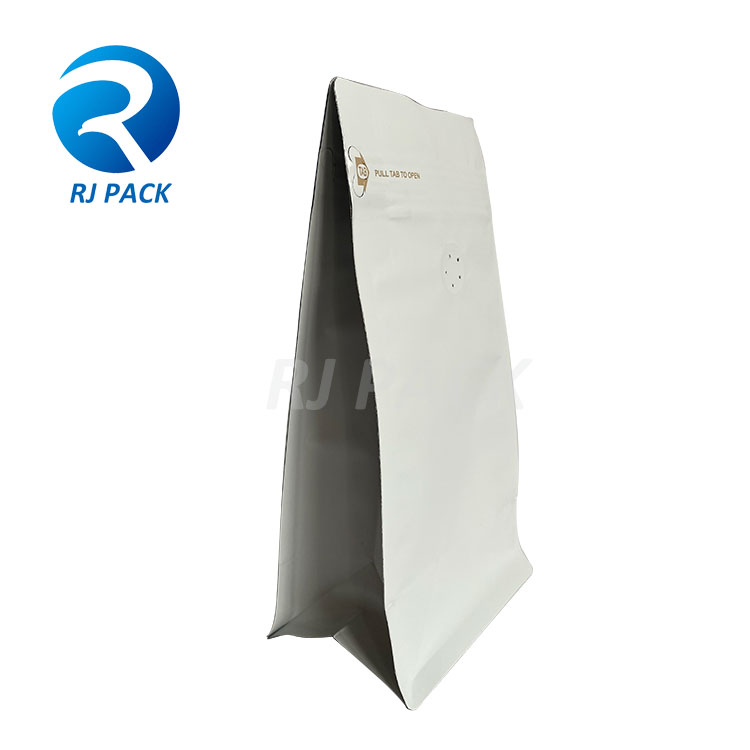

2). provide a versatile packaging method for a wide variety for boiled food.Suitable for all kinds of vacuum machine,quickly vacuumize and excellent sealing

3). After going through a retort machine, the food and package are able to withstand temperatures up to 250 degrees, making this the perfect solution for microwavable meals.

4). Retort Pouches can be used for products such as soups and sauces, seafood, pet food, and ready-meals, etc.

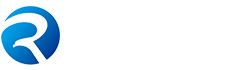

4.126℃ Retort pouches Details

There are usually 3-4 layer, with tear notch. Stand up pouch and three side seal bag are commonly used. It can boil for half an hour at the temperature that up to 121℃

5. 126℃ Retort pouches Qualification

The materials we used are FDA and EU approved, and our factory has obtained BRC and ISO certificate.

6.Deliver,Shipping And Serving of 126℃ Retort Pouches

The lead time takes about 20 working days, and the transport time is estimated according to different regions. All the goods will have full inspection before shipping out.

1). By Express (3-5 working days), suitable for Urgent Time and Small Quantity.

2). By Sea (15-30 days), suitable for regular Mass Production.

3). By Air (5-7 days), from Airport to Airport.

7.FAQ

1.How long is your delivery time?

I will take 20 - 40 days according to order quantity of 126℃Retort Pouches

2.What certificates do you have?

We have BRC, HACCP, SGS And ISO. And we have recyclable and compostable certificates for these environmental Retort Pouch as well.

3. How many years has your company been established?

Our company established in 2003

4 What's your MOQ

10,000 pcs for pouch and 200g for film

5 Do you have office overseas?

No, we are factory in China and we don’t have office overseas

6 Are you a factory and can you provide packaging solution?

Yes, we are experienced factory that stand for nearly 20 years. We have rich experience in providing packaging solution for your products.

7 What's your main products?

Our products include stand up pouch, gusset bag, Flat Bottom Pouches, 2/3 side seal bag, spout pouch and roll stock film, etc. And we have rich experience at producing recyclable and compostable PTC Zipper Stand Up Pouches.

8.Video